Smart Field Services

More profitable services, more productive customers

With data from sensors, devices, and connected equipment, you can tell when your customer’s assets need servicing, and exactly what intervention is needed. Send technicians to field sites only when they’re needed—and complete the job on the first visit. Targeted services that help your customers maintain greater uptime also increase your value as a strategic provider of aftermarket parts and services. Climb the IoT maturity curve with smart field services.

Smart field services elevate your customers’ experience to a completely new level. By offering prompt services that meet their needs and help them maintain uptime, you become a critical partner for your customers’ success. Greater customer loyalty improves customer retention and builds your reputation, fueling new product sales.

Operate smarter with smart field services

Avoid costs from asset downtime

The average cost of an hour of downtime has more than doubled over the past five years to over $250,000. Empowering field service teams with direct knowledge before they arrive will allow them to work quickly and minimize unplanned downtime. IoT delivers insights to plan services and eliminate corrective needs.Increase first time fix rate (FTFR)

A service visit from an unprepared technician is only going to waste time and degrade the customer experience. With insights from IoT connected equipment, you can perform remote diagnostics to understand the condition of customer equipment. Schedule technician visits based on real need and optimize routes to reduce unproductive visits and increase first call repair rate.Optimize component management

With insight into the real-time status of equipment in the field, you can better manage spare parts and components. Become a trusted supplier of spares for your customers—and capture more aftermarket revenue—by aligning inventory of critical spares with expected replacement needs.Provide guidance to the customer without going onsite

Condition monitoring enables data-driven understanding of equipment performance and conditions, so the equipment maker can use high-value technical service teams more efficiently, reducing the number of service visits needed and making each visit more productive.The numbers tell the story

$9 billion

global market for field service management by 2030, driven by increased adoption of AI and IoT solutions.

Source: Market & Markets

40%

reduction in costs associated with IoT-powered smart field services.

Source: SAP

10%

increase in customer satisfaction for companies with higher than average FTFR compared to those with lower than average FTFR.

Source: Aberdeen Research

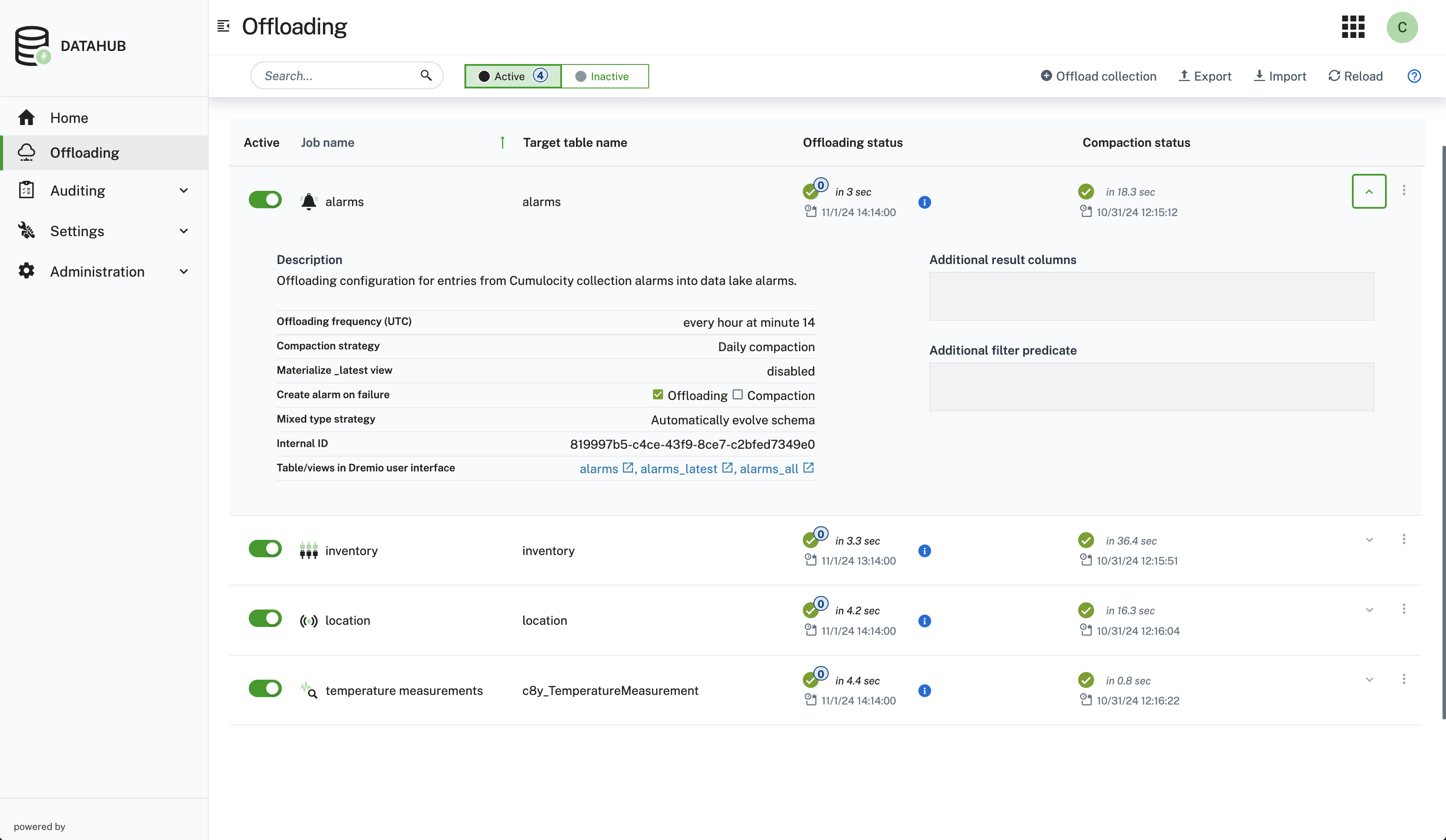

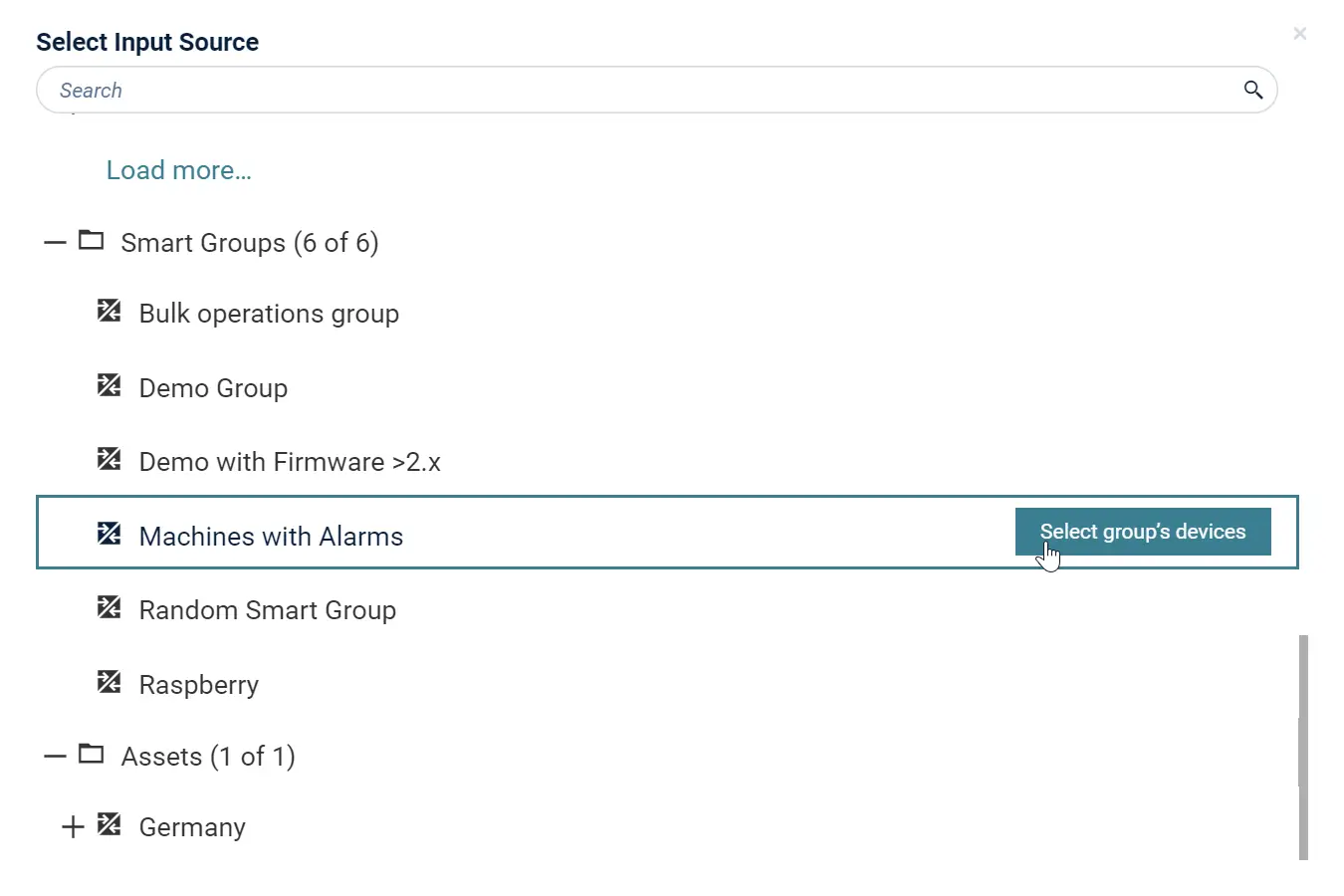

Easily connect and collect data from your assets

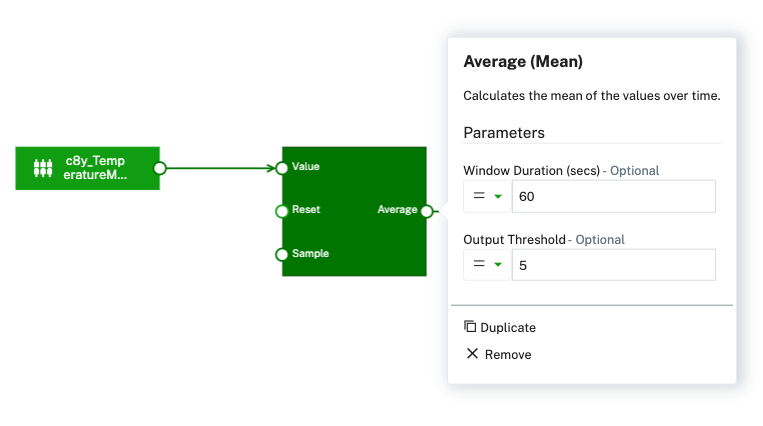

Turn raw data into actionable insight

Deploy pre-built analytics templates to match your specific equipment characteristics and customer needs. Integrate AI models seamlessly with Cumulocity and operationalize it on incoming IoT data from your connected devices. Utilize Streaming Analytics to effortlessly feed live IoT data into your model and let it generate actionable insights and drive impactful actions.

For more information, visit the Cumulocity documentation.

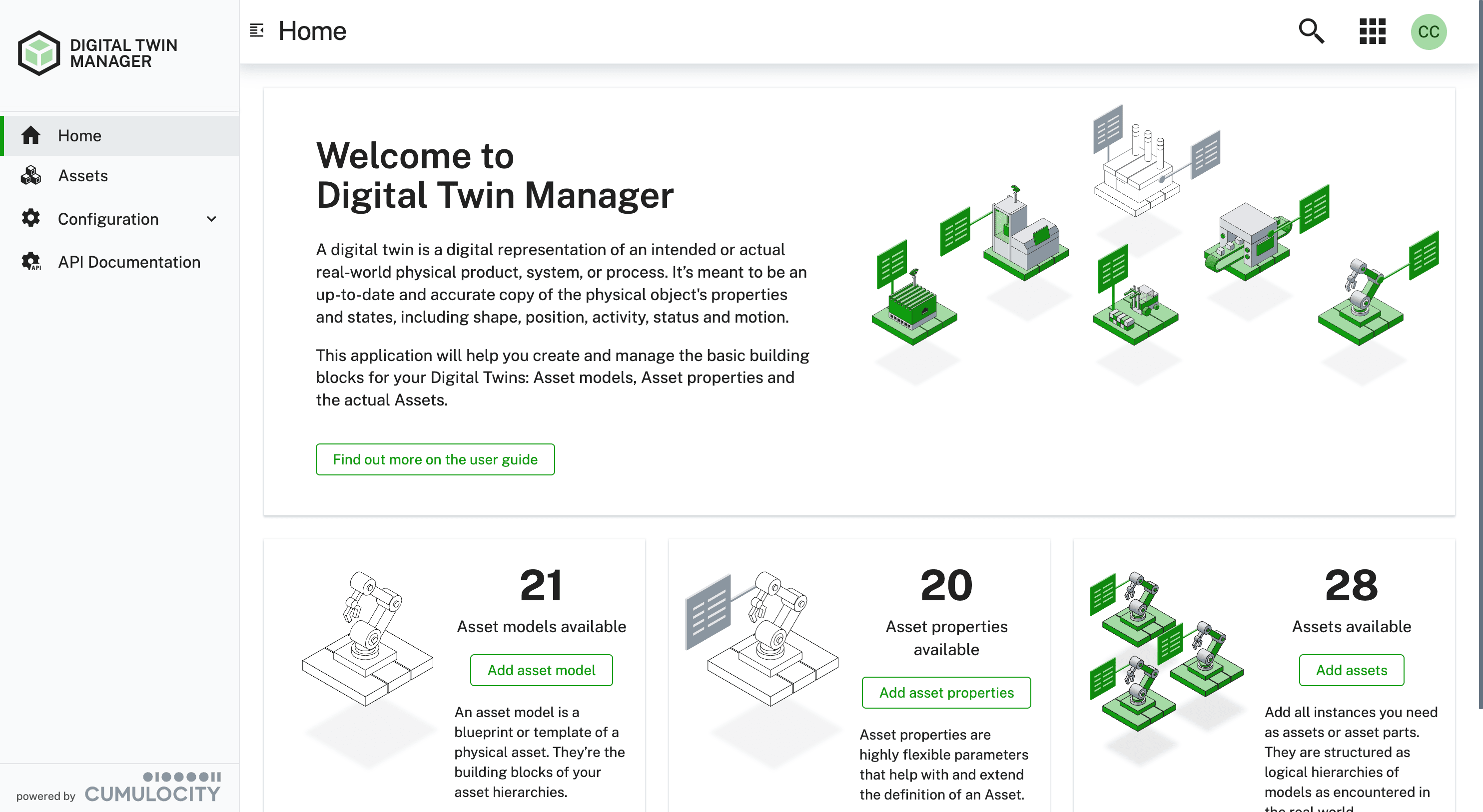

Build a digital representation of your physical assets

Make data available across the business