whitepaper

Understand (and overcome!) the challenges of building smart products

The IoT Imperative

Original equipment manufacturers (OEMs)—especially those making premium industrial equipment, machinery, and devices—are under increasing pressure from all sides. Supply chains are more complex and volatile than ever. Skills and labor shortages are ever-present. And buyers’ expectations continue to grow. To thrive, even to survive, you must rethink differentiation and value.

As Vele Galovski, VP, Research, Field Services & IoT, TSIA, said, “The concept of make, sell, ship is history.”

The ability to gather real-time insights into their customers, products, and equipment is a crucial part of a manufacturer’s competitive arsenal. Data is more available today than ever before, and companies need to make sure they’re using it effectively to stay competitive. Without it, you’ll be fighting to stay relevant and adapt to changing circumstances with one hand tied behind your back.

The Internet of Things (IoT) opens up incredible opportunities to connect “things” and change how manufacturers operate, market, and serve their customers. It can provide far greater insight, require fewer resources, and do it all at less cost. It’s core to many, even most, of the innovations we see transforming industries, from consumer goods to industrial equipment.

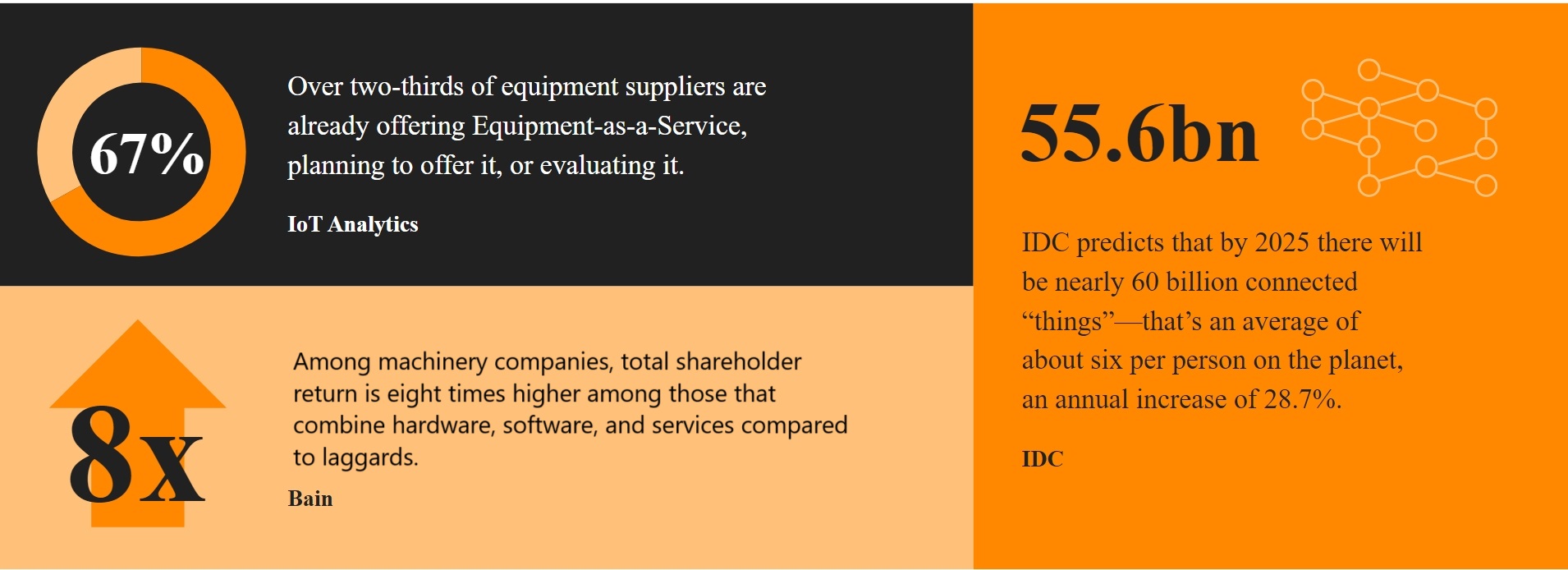

Companies that are further ahead in the transition from equipment businesses to integrated solutions businesses have delivered higher total shareholder returns over the past three years.

- Bain & Company, The Hardware Paradox: Machinery Must Expand Beyond Machines

The possibilities created by connecting equipment are much more than hype. Doing so can bring real, tangible results. When the collected data is used effectively, and turned into actionable insights, the benefits can be vast and wide-ranging.

Interest in connecting equipment is being driven by both demand-side and supply-side factors. Everything from entertainment services to plant equipment, cars to MRI machines, are available as a service. Buyers aren’t just comfortable with smart, updatable products and new ways to acquire them; a growing number of business customers expect them. Increased use is also being driven by the maturity of the technology. Sensors have gotten much smaller and cheaper, there’s more experience of how to make projects successful to draw on, and analytics and processing capabilities have improved many-fold.

Wherever you are on your digital transformation journey, connected devices could help you to achieve your business objectives.

Connected equipment and the IoT maturity curve

Expectations of your customers, management, and business partners are changing fast. The challenges aren’t exactly new, but the urgency has grown exponentially. As a manufacturer, you’re on the hook to:

- Improve efficiency and reduce waste.

- Shorten development cycles.

- Deliver better customer experiences.

- Diversify revenue sources and increase sustainability.

- Increase business agility.

Everybody knows that digital transformation is essential to meet these challenges, but it’s not something that you can buy off the shelf. There is no one-size-fits-all approach that will work for all companies.

A well-executed tech-enabled transformation will have direct impact on revenue growth, margins, and new revenue streams from new business models or services.

- McKinsey, Tech-enabled transformations, a CEO’s guide to maximizing impact in industrials

It’s widely accepted that IoT is a core enabler of business transformation, along with technologies like artificial intelligence (AI) and edge computing. For some, the power of IoT is off-putting. The sheer variety and magnitude of what you can do leaves them like a deer in headlights.

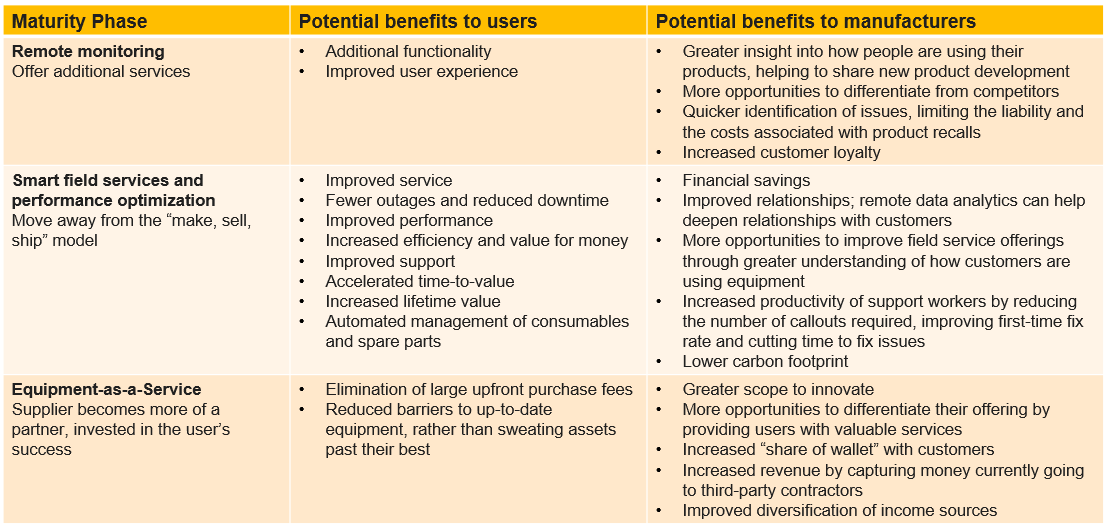

But there’s good news. You don’t have to leap all the way to an Equipment-as-a-Service model to benefit from IoT and connected devices. There are compelling benefits associated with each phase of IoT maturity (see diagram). And those benefits are cumulative. This means that there are strong reasons to get started, and to continue along the journey.

Phase 1

At its most basic, IoT can enable manufacturers to augment their products with new features to meet growing customer expectations and differentiate. This could include revenue-enhancing services, including service reminders, consumables ordering, and data recording/visualization services that can improve the user experience.

Who benefits?

-

Users get additional functionality

Adding even basic connected device functionality can help improve the user experience.

-

Manufacturers get insight, differentiate products, and build loyalty

Connected device functionality can help manufacturers understand how people are using their creations. The data gathered could help shape new product development and identify issues more quickly—potentially limiting the liability and cost associated with product recalls. Connected services could also help differentiation with competitors, building preference and loyalty. Phase 1 is the first step in moving away from the make, sell, ship model to an ongoing relationship model.

Case study: Dürr cuts waste and reworks with smart painting systems

Dürr is a world leader in the manufacturing of paint shops. Its systems are used by every major automaker in the world. Its systems were already highly automated, but its customers wanted more. Working with Cumulocity, it has developed robots with up to 100 sensors each. The system can stream up to 10,000 readings per second to an edge-based analytics system that can spot issues like blocked nozzles, contaminated paint, and air bubbles. By cutting the time to spot problems, the system can cut costly rework and reduce waste. It’s also saving energy by optimizing when paint heads need to be heat cleaned, rather than sticking to a fixed cycle.

Read how Dürr is saving its customers time and money, while reducing energy use and waste.

Phase 2

IoT and optimization go hand-in-hand. Connected equipment enables manufacturers to offer smart field services, which can help to reduce costs and create new revenue streams.

Equipment manufacturers/owners are also able to offer additional services, such as maintenance, that the user may have done themselves or contracted out to a third-party in the past. By fully leveraging the potential of IoT, owners could provide predictive maintenance, reducing the risk of downtime, extending the life of the asset and providing a valuable service to the user. Owners are also using IoT to innovate and provide a wide variety of additional services, including automatic ordering of consumables.

Who benefits?

-

Users get improved services

Connected equipment technology can help reduce outages and increase uptime. Remote analytics can help improve performance, increasing efficiency and improving value for money. Connectivity also enables manufacturers to provide support, often automated, to guide users through the installation and commissioning process. As well as improving the user experience, this can help accelerate time-to-value and lifetime value. Ongoing communication also enables automated management of consumables and spare parts.

-

Manufacturers get savings and improved relationships

Remote data analytics can help deepen relationships with customers, increasing loyalty. Data-driven understanding of equipment use, and conditions can help manufacturers to improve their field service offerings. By reducing the number of callouts required, improving first-time fix rate, and reducing the time taken to fix issues, manufacturers can substantially improve the productivity of support engineers while cutting response times and reducing their carbon footprint.

Case study: Flexco improves customer service with connected products

Flexco is a leading industrial conveyor belt products and services company. Many of its products are used in remote, hard-to-access, and even dangerous environments, like quarries and mines. The consequences of a conveyor failing can include loss of production and even risk of damage to equipment or injury to people. The belt is the part most vulnerable to wear-and-tear and it must be regularly monitored for damage, misalignment, and loss of tension. But manual inspection can be expensive and dangerous. The answer was to develop connected conveyors with continuous automated monitoring using IIoT sensors and a robust IIoT platform. As a result, Flexco is improving uptime and reducing maintenance costs.

See how Flexco and its customers are benefiting from IoT and smart field services.

Phase 3

Equipment-as-a-Service is a business model where instead of selling equipment, manufacturers rent it to end users. But it’s much more than that. Ultimately, it can enable customers to pay for defined outcomes that better match their needs, while generating opportunities for equipment makers to offer high-margin services and enhance their products with data-driven insights.

Using connected device technology, equipment owners can price rentals on more meaningful measures than simply duration of hire. The ultimate goal is to measure outcomes: This could be liters processed, hours flown, units produced, batches completed, or a million other things.

Who benefits?

-

Users get flexibility

The elimination of the large upfront purchase fee means that users can free up capital for other priorities. They are motivated to keep up to date, rather than sweating assets past their best. And their supplier becomes more of a partner, invested in the user’s success with their products.

-

Manufacturers can innovate

They can differentiate their offering by providing users with valuable services. This can help grow “share of wallet” with a customer, capture revenue currently going to third-party contractors, and diversify income sources.

Case study: WAINS brings “as-a-Service” to pest control

You probably don’t spend long thinking about pest control. Right now, you’re likely to be picturing something you saw in a cartoon. That picture couldn’t be further from the truth of modern pest control. WAINS is a relatively new company, but it’s making waves in the industry. Working with Cumulocity, it has developed a smart solution that turns pest control into a modern, customer-oriented service. Its “insect cloud” enables real-time remote monitoring, resulting in enormous time and cost savings. By being able to detect infestations faster, its customers can mitigate damage and avoid regulatory issues. WAINS offers its product, traptice, under a flexible leasing model. New customers can try out the devices risk-free and upgrade their subscription when they see the benefits for themselves.

Read how WAINS is bringing IoT, AI, and automated real-time monitoring to pest control.

What’s holding you back?

The good news is that the IoT provides a platform to deliver smart, connected products and innovative services to differentiate, grow, and increase customer loyalty. So, what’s the catch?

The challenges with IoT projects are the challenges with any transformation project. They fall into four categories:

- Ideation and prioritization

- Implementation

- Skills and expertise

- Cultural and process transformation

Overcoming the challenges

The right approach can enable you to build true enterprise-grade connected assets, where systems are more closely integrated, processes are better connected, employee and customer experiences are seamless and effortless, and information and insights flow more freely.

Strategy

Teams may set out trying to “boil the ocean.” A company that’s unfamiliar with IoT jumping straight to an Equipment-as-a-Service model is a bit like a first-time ice skater attempting a quadruple axel. It’s normally easier for organizations, especially established ones adapting products rather than a start-up starting from scratch, to take a phased approach, following the IoT maturity model.

Conversely, technology teams can easily get bogged down by details—adjusting a setting here, a parameter there, or trying to integrate components from different vendors. This causes teams to lose sight of the intended business outcomes. Their projects often fail because decision makers lose patience and pull the plug when they don’t see tangible results quickly enough.

Focus on the “art of the practical” and take a measured, progressive approach. And always, especially as you grow in maturity, look at your connected device project from the end-user’s point of view.

Implementation

One of the critical decisions when implementing an IoT project is “build or buy”:

- Building a solution yourself means that you have total control, and you can build something completely bespoke. It could also lead to problems getting the right talent, project delays, and having to learn through trial and error.

- Buying a solution comes with the risk of paying more and having less control—though it doesn’t have to be like this. An experienced third-party could help you to navigate the pitfalls, reduce the total cost of ownership, and bring in knowledge from other industries that could prove invaluable.

But why choose? It doesn’t have to be an either-or decision. A “buy and build” approach could give you the best of both.

Buy & build: The benefits

Focus on addressing how you can generate value for your organization with IoT. The faster you produce tangible business outcomes, the more support you will gain for your project and the sooner it will become part of standard operations. Employ a “buy and build” strategy and leave the technology for building IoT to those who have made it their business.

Faster to build:

- Avoid skill shortages.

- Work smarter.

- Accelerate solution development by leveraging proven solution component.

Faster to value:

- Avoid costly mistakes and vendor lock-in.

- Accelerate value by learning from the experiences of others.

Faster to grow:

- Build scalability in from the outset.

- Leverage open source to avoid limiting proprietary technology and keep your options open.

- Upskill your people.

- Scale and make changes faster with a self-service platform.

- Extend the reach of your IoT solution, faster.

Finding the skills—and hanging on to them

There always seems to be a skills shortage. The problem is particularly acute in leading-edge technologies, like IoT. Successful implementation of even a basic IoT project requires close integration of multiple skills. Even many technology companies lack depth and breadth of experience with IoT solutions.

Not least of the specialist skills required is cybersecurity. IoT, especially mass IoT, requires a change in security mindset. In the early days of IoT, it was common to read about researchers demonstrating proof-of-concept attacks on devices. Things have changed a lot since then, but as the understanding of the problems has improved, so have the stakes. The attacks have evolved from theoretical to a day-to-day reality. And the consequences of a failure can be extreme:

- The more critical connected devices become to how you, and your customers, do things, the bigger the problem is when they don’t work.

- The volume and importance of data gathered is growing fast, elevating the consequences of exposure.

- Stealing data isn’t the only way to compromise a company. Tampering with data could lead to ruinous consequences—and not just financial impacts: Look at the attacks on water-processing plants and other critical infrastructure, for example.

- Connected devices can be a gateway to other devices and systems, including cloud-based applications.

Culture

Technology is crucial but is only part of the solution. Successful IoT projects require a significant cultural shift throughout the organization. Industry experience is a pre-requisite for any partner, but is really only table stakes. Any of your partners should demonstrate that they understand your objectives. They should be able to help you accelerate your IoT journey, but respect the cultural concerns, internal and external, that dictate the right speed for your transformation.

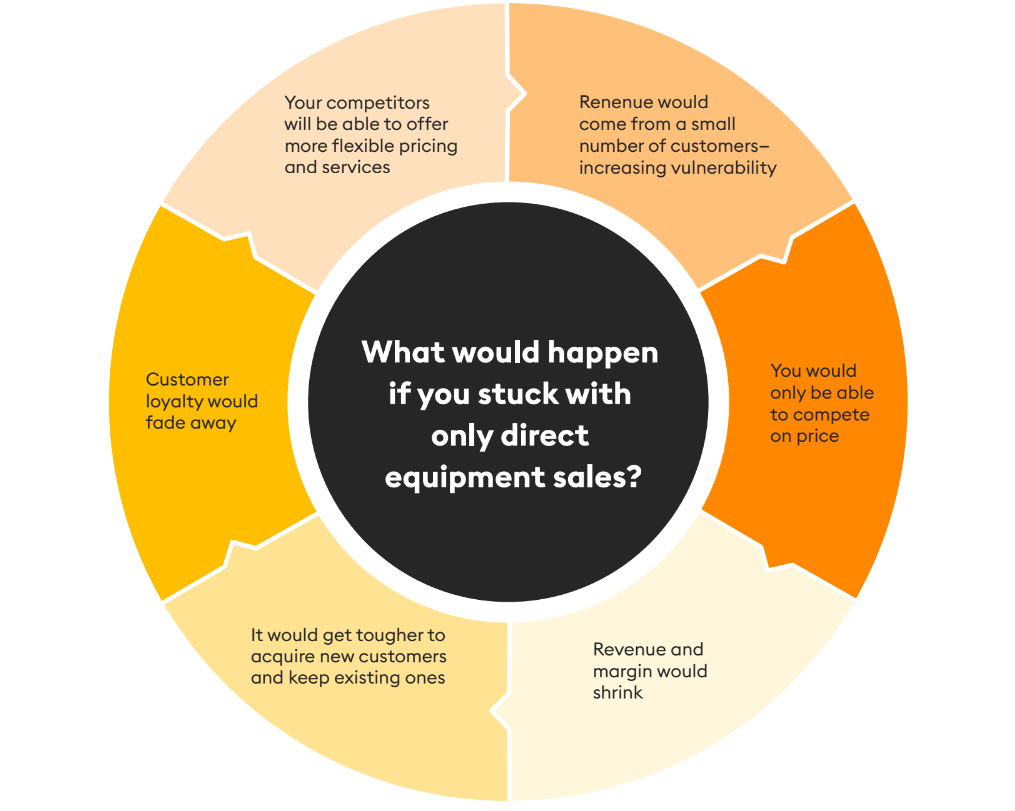

Make the switch, before your customers do

It may feel like you have time, but things move fast. Consider this, what would happen if you stuck only with direct equipment sales?

Leverage the possibilities of connected devices to:

- Tailor services to customers based on their needs and wants.

- Increase your strategic value to your customers.

- Create resilient, recurring revenue streams.

- Shorten innovation cycles with faster product releases.

- Innovate and differentiate to create new business models.

What’s stopping you now?

Don’t get left behind

Cumulocity understands what it takes to make a connected product strategy work. Wherever you are on your journey, we can help you achieve more. Our approach focuses on going at the speed that’s right for your organization and customers, while always striving to deliver “faster to build, faster to value, and faster to grow.”

Take the next step

Companies are doing great things with IoT, you can too

Learn what’s possible on Cumulocity, a leading global, low-code, self-service IoT platform.