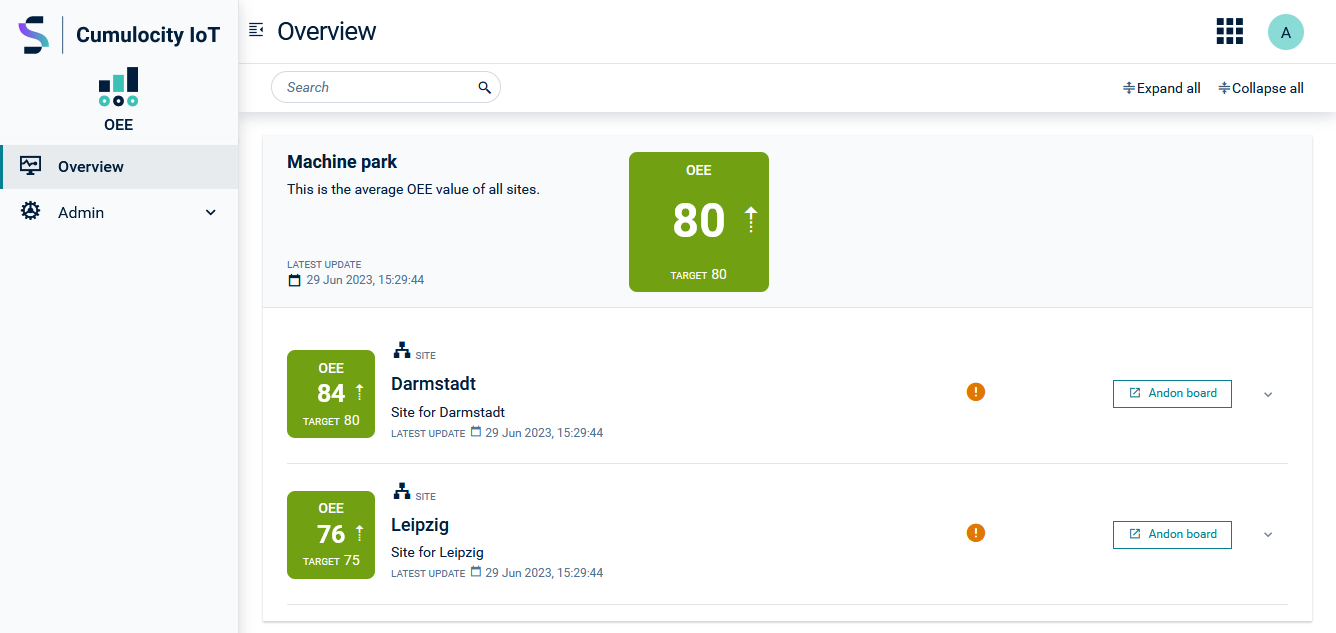

Machine Park Overview

The Overview page is the landing page of the OEE application. Here you can find aggregated information on the OEE values of your machine park.

Depending on the defined target value, the OEE box for an entity is either displayed in green (above threshold) or in red (below threshold). The particular value and the threshold are also shown in the OEE box. An arrow on the right of the OEE value indicates the current trend - OEE increasing (the arrow points upwards), decreasing (the arrow points downwards), or no change (the arrow points to the right).

New values are calculated at regular intervals. This interval is influenced by the default value set in the machine, line and site profiles. The latest update information shows the precise timestamp. If a machine is not currently in an active production shift, this will also be indicated there.

In the upper section, the average OEE for the entire machine park is shown, that means, the average OEE value of all sites for which OEE values are listed in the Machine Park Dashboard.

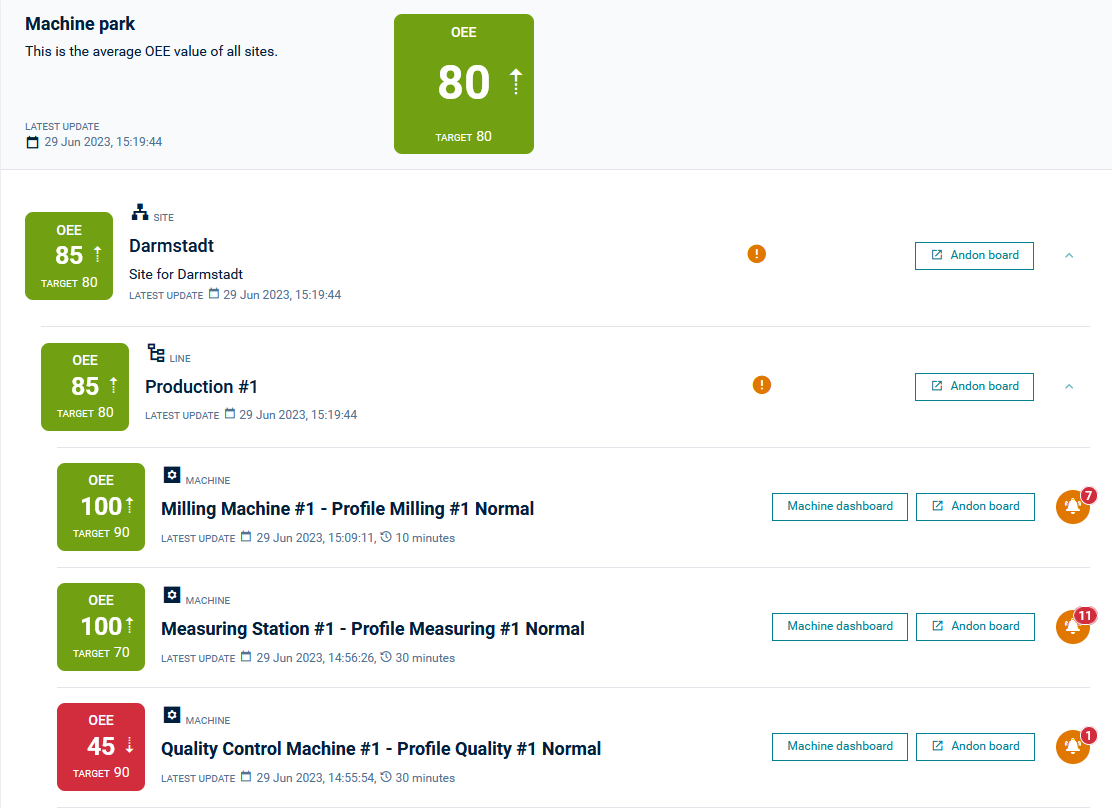

Below, the OEE for the areas, sites, lines and machines are displayed.

Clicking the arrows expands (or collapses) an entity and shows (or hides) the entities assigned to it.

The OEE value for an entity is calculated as the average or the product (see below) of the associated entities that follow in the hierarchy. The hierarchy is as follows: Site > Area > Line > Machine.

For sites, areas and lines you can select one of the following options for the OEE calculation:

- the average of the attached entities

- the product (percentages) of the attached entities

This can either be configured when creating an area, site or line profile or set later under Administration > Organization, see Organization.

In the search field at the top left you can search for specific sites, areas, lines and machines by searching for their profile name.

Click Andon Board at the right of an entry to switch to the respective Andon board, see Andon board.

Click Machine dashboard at the right of machine to switch to its Machine dashboard, see Machine dashboard.

An orange alarm icon at the right of an entry indicates an alarm within this entity, together with the number of alarms shown in red.

Orange/Blue dot - Indicates an alarm within this entity. The color of the icon depends on severity of the alarm.

Orange alarm icon with number on top - Displays the number of alarms on the machine or the production line.

Orange spanner icon - The profile within the entity is not fully configured.

Blue cloud icon with clock symbol – The profile did not receive measurements yet.

White square within a grey or black circle - Indicates that the profile is deactivated and no new measurements are being received.

The color of the alarms depends on the priority of the alarms. In general, the color of the alarm with the highest priority is always displayed.

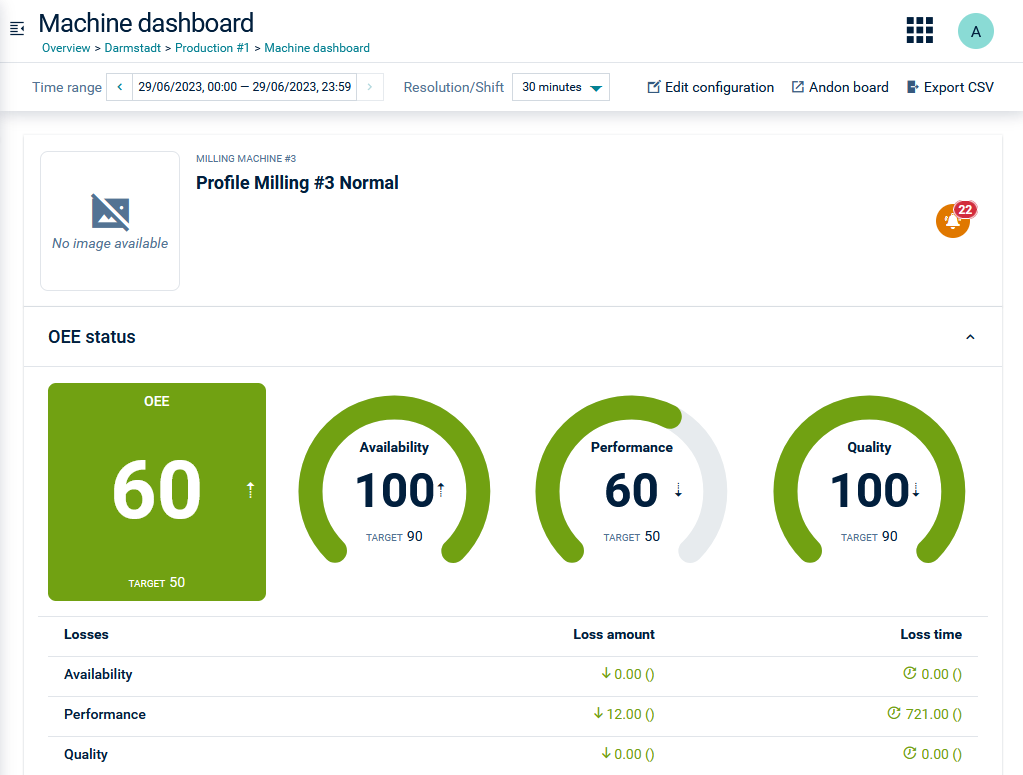

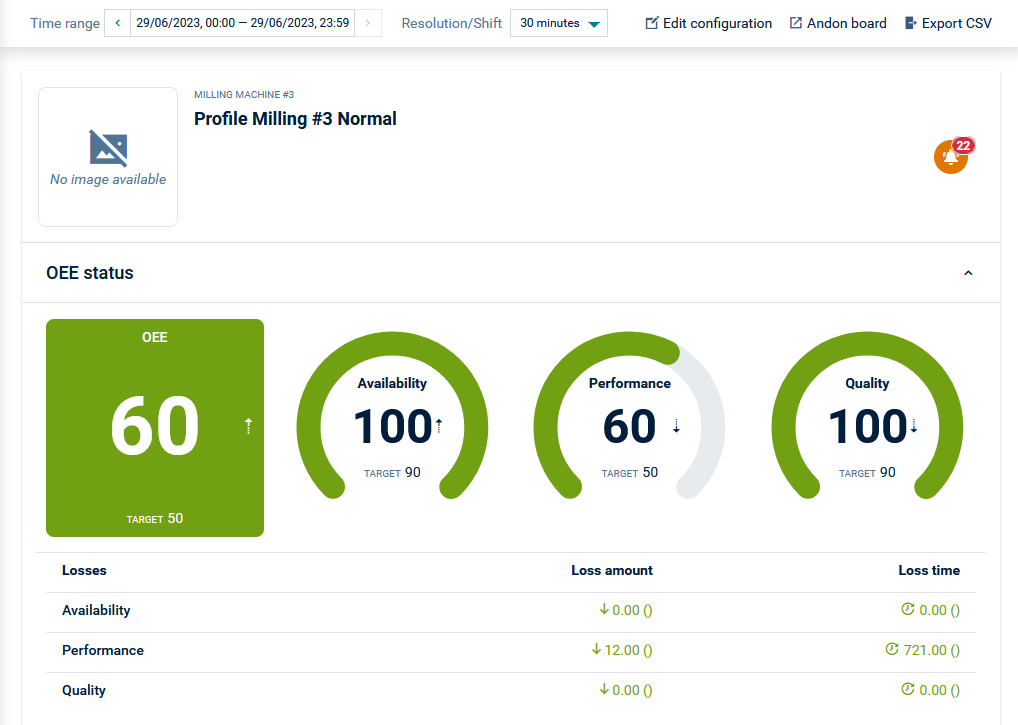

Machine dashboard

The machine dashboard offers a detailed view about the current status and development of the OEE of the machine.

At the top you find the general information (such as profile name or alarm status) provided in the Machine Park Overview, followed by the OEE status section and OEE data section.

By default, the Auto-refresh option at the top left is activated and OEE status and OEE data information is updated automatically according to the selected resolution. Switch the toggle to deactivate it.

Click Andon Board at the right of the top menu bar to switch to the Andon Board of this particular machine, see Andon Board.

Click Edit configuration at the right of the top menu bar to edit the machine profile in the profile configurator, see Creating machine profiles. This link is only visible if the user has a role assigned with the Oeeconfigurator Admin permission enabled.

Time period and resolution

In the Time range field you can select a time range for which the OEE values will be displayed in the OEE status and OEE data sections. By default, this will select a 24-hour period based on the current date. The back and forward arrows will move the time range based on the difference betwen the start and end time, that is, if the difference between the two times is 4 hours, then the arrows will use steps of 4 hours.

In the Resolution/Shift dropdown menu you can select the resolution for the selected time period. The available resolutions as well as up to four default periods (for example, 1 minute, 10 minutes, 1 hour, and 8 hours) are configured during the profile creation. For more information see Creating machine profiles. It is also possible to directly select shifts for that machine’s location as the resolution.

OEE status

In the OEE status section, the values for OEE, Availability, Performance and Quality according to the selected time frame and resolution are shown.

Below these values the losses caused by Availability, Performance and Quality are displayed in terms of time and amount.

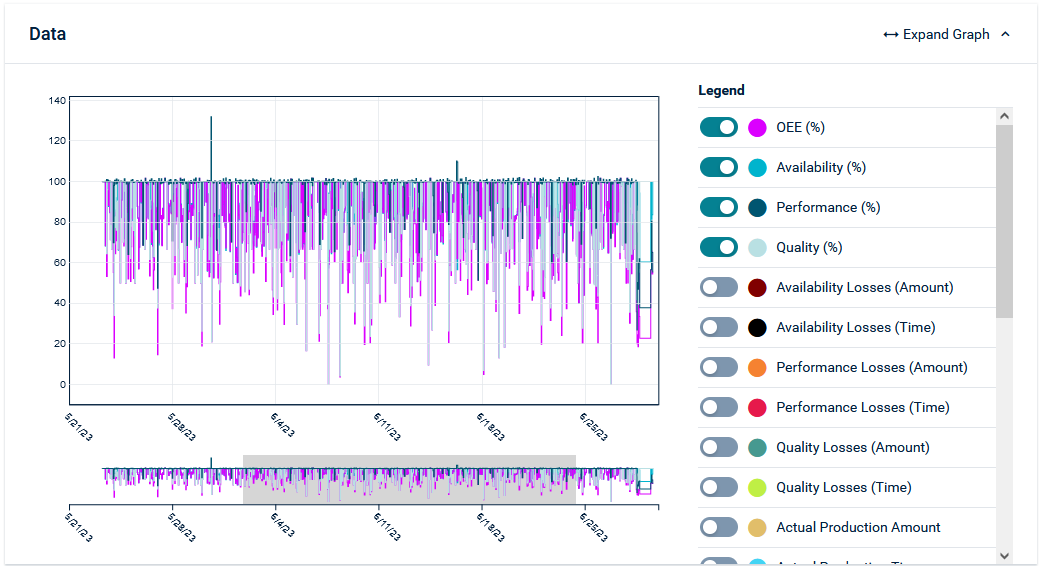

Data

In the Data section, a chart is available to display the current values of selected components over the specified time frame. Each of the specific items, such as OEE, Availability, Performance, and Quality, can be selected at the right by activating/deactivating the respective toggles. A toggle also exists to overlay alarms on the graph. In this way, it is possible to correlate the alarm event with other measurements.

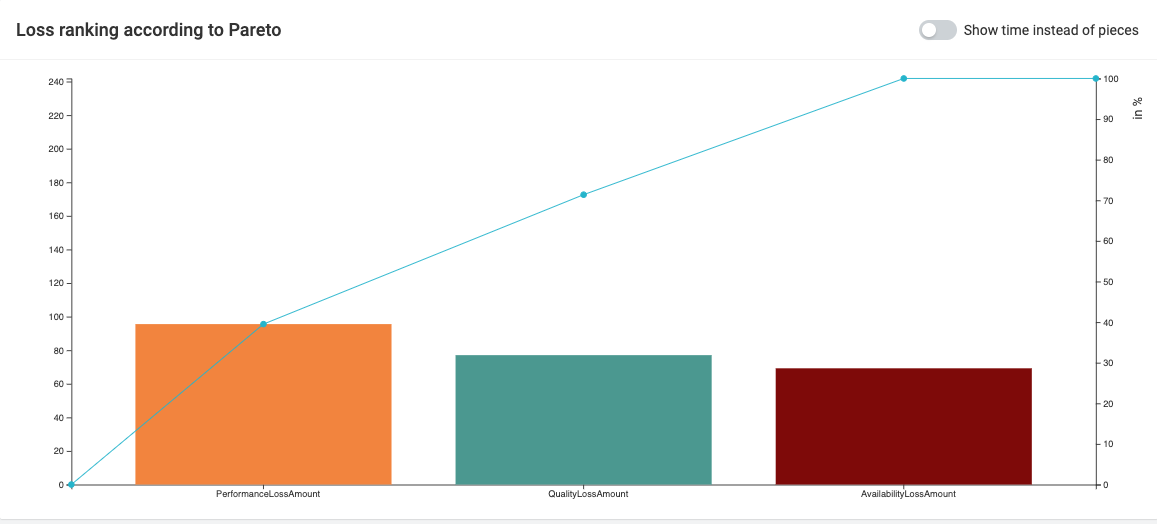

Pareto chart

The Pareto chart shows the loss ranking according to Pareto. The Pareto principle assumes that 80 % of the losses can be attributed to 20 % of the causes of defects.

The losses can be shown in relation to pieces or time by switching the toggle at the top right.

If all losses are 0, the OEE is 100%. Since this is not possible in reality, as OEE is always measured against an ideal, there are always losses shown in the Pareto chart.

The faults that cause the most damage are listed first. It thus supports the decision-making by recommending the order in which the causes of faults should be eliminated.

In the Pareto chart on the right, all losses, divided into the areas Availability, Performance and Quality, are displayed and put in relation to each other. In this case, the Availability Losses make up 52.74% of the total losses. In a future version, the three main losses can be divided into further categories to better identify sources of faults.

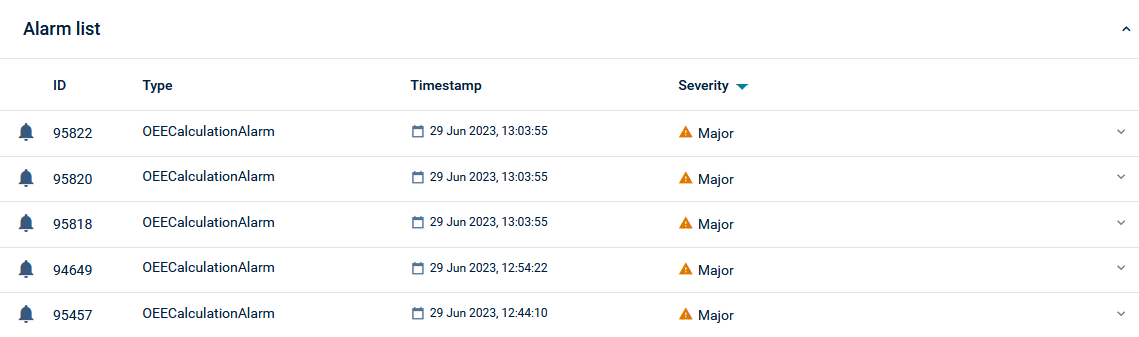

Alarm list

Click the alarm icon at the top to display the alarm list at the bottom of the machine dashboard.

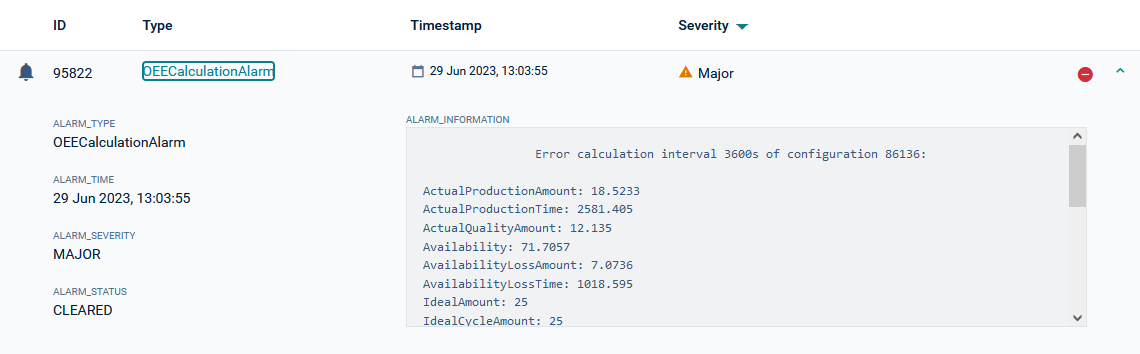

The alarm list shows the following information for each alarm: ID, type, timestamp (time of occurrence) and severity.

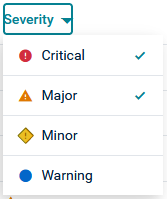

The alarms can be filtered by severity:

Clicking the arrows expands (or collapses) the alarm and shows (or hides) more detailed information.

To delete an alarm from the list, click the remove icon at the right of the respective row.

Export CSV

Click Export as CSV at the right. The Export page in the Cockpit application will open.

-

Click Add export in the top menu bar.

-

Enter a name for the export and select the file type (CSV is the default) for the output.

-

In the Filters section, select Objects to export, enter the profile name to be exported and select it from the list.

-

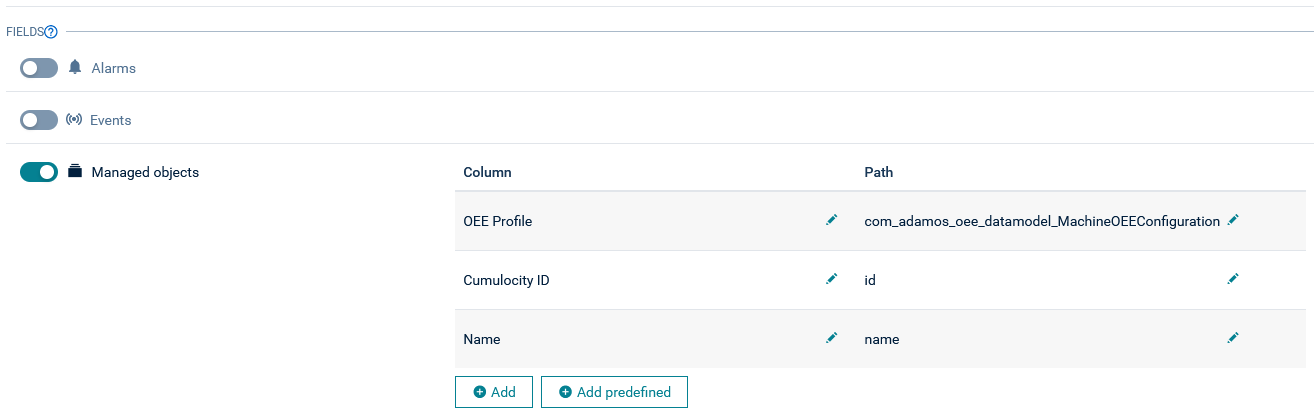

In the Fields section, turn Managed objects on, and add the following columns:

- OEE Profile > @com_adamos_oee_datamodel_MachineOEEConfiguration

- Cumulocity ID > ID of the OEE calculation profile

- Name > name

InfoColumn names are user defined, whereas the path is the fragment name of the managed object. -

Click Save & close to save your configuration.

-

Select the checkbox in front of your export in the export list and at the left of the top menu bar click Export.

An email will be sent to the user email address containing a link to the export file.

See also Managing exports for details on the export functionality.

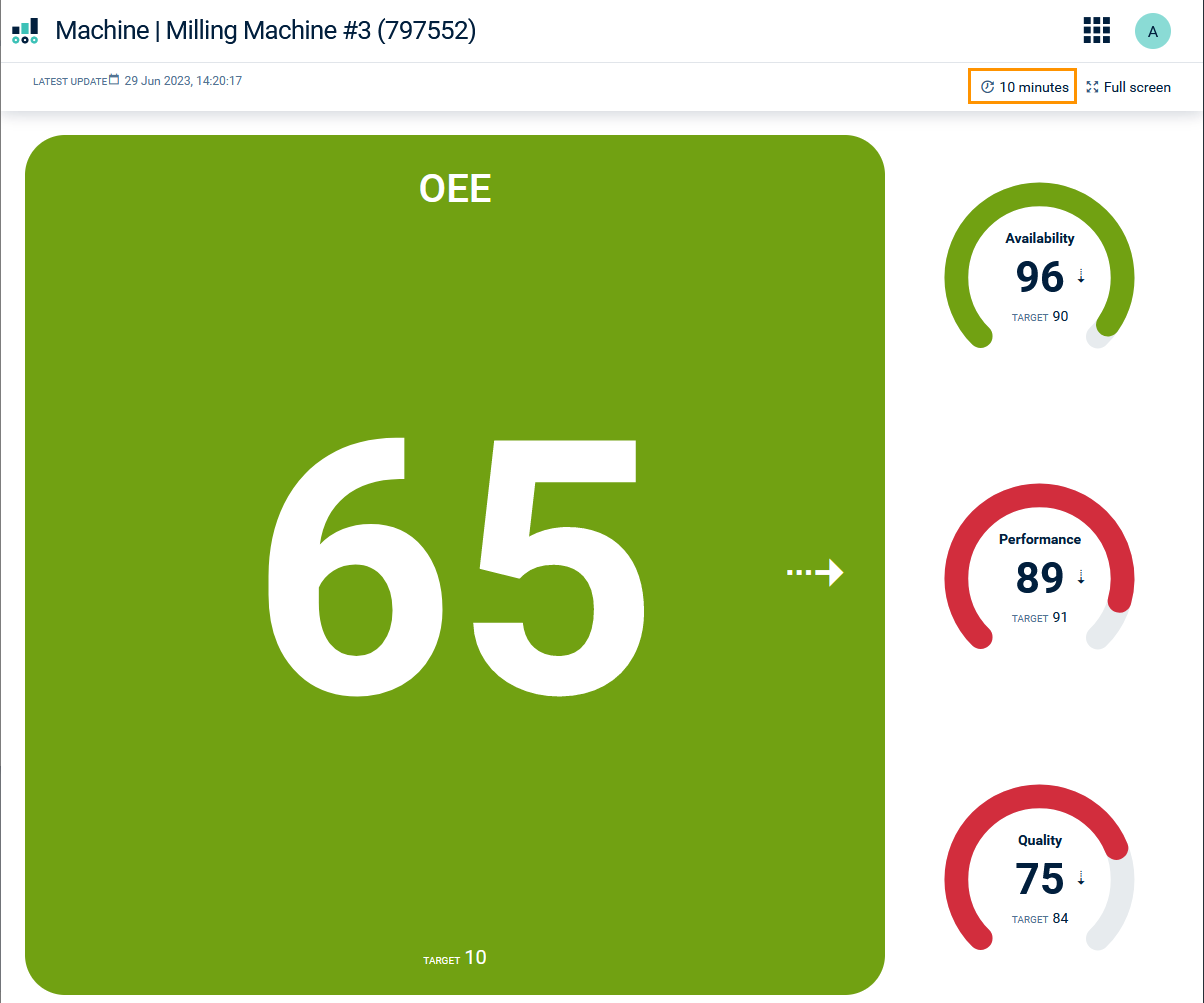

Andon board

The Andon Board displays and constantly updates the values OEE, Availability, Performance and Quality for each entity in the Machine Park Overview.

The update interval of the values in the Andon Board for sites, areas and lines will be determined by the default update interval of any machines contained inside it. Every time a machine updates, calculations will be propagated upwards in the structure. It is not possible to change this update interval.

For machines, the update interval is the default value set in the machine’s profile, but can be adjusted by clicking on the interval at the top right, next to Full Screen. It is also possible to select individual shifts as the interval. The last update time is given at the top of the page above the OEE values. If the machine is not currently part of a productive shift, this will be indicated here also.